Stainless steel is a high-alloy steel that can resist corrosion. It has a beautiful surface and does not need to be treated by coloring or painting. Therefore, many machinery factories often do not do any paint treatment in order to show that they are stainless steel. Stainless steel has a beautiful appearance. Appearance, corrosion resistance, not easy to damage and other advantages, widely used in all walks of life.

1. Simple classification of stainless steel

Stainless steel can be roughly divided into three categories: 200 series, 300 series and 400 series. Among them, 300 series is the most commonly used, and 200 series and 400 series are substitutes for 300 series to a certain extent. Strictly speaking, 400 series is not called stainless steel. , called stainless iron, because it does not contain nickel, so it can be attracted by a magnet. The 200 series and 300 series are made of nickel, so they are non-magnetic and cannot be absorbed by iron.

304 is the most common variety in the 300 series, so generally the price trend of the entire stainless steel can be judged from the price change of 304. The 200 series contains less nickel, the 400 series contains no nickel, and the 300 series contains the most nickel, so the 300 series is most affected by the price of nickel.

The 300 series can be simply divided into 304, 304L, 316, 316L, 321, 309S, 310S, etc. The basis for the distinction is that the contents of various metal elements are different, and the characteristics of stainless steel with different contents are also different. The difference between 304 and 304L is that The carbon (C) content is different, the one with L means low carbon content, also called low carbon, and the difference between 316 and 316L is the same.

2. Morphological classification of stainless steel

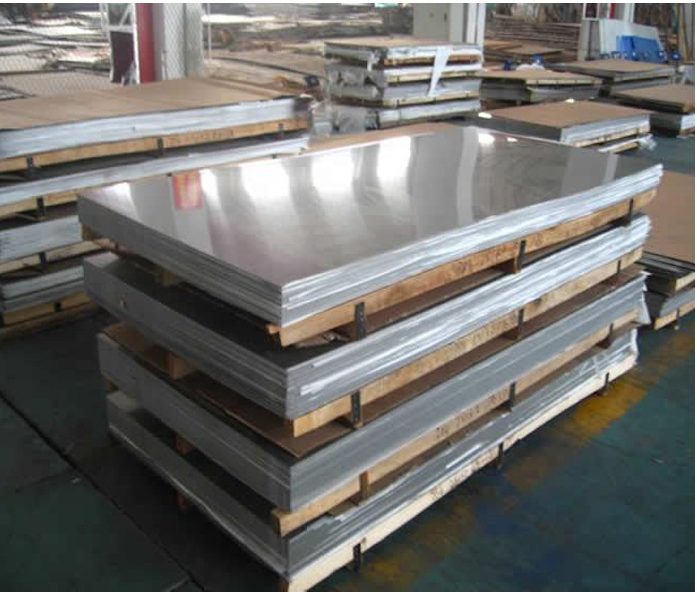

Stainless steel can be divided into five categories: coils, plates, profiles, steel pipes and parts, the most important being coils and plates. Profiles are materials of various shapes made of plates, including angle steel, flat steel, I-beam, and channel steel. Steel pipe mainly refers to seamless steel pipe, and the opposite of seamless steel pipe is welded pipe. The difference lies in whether it is formed at one time. Parts mainly refer to elbows and flanges and other small things.

The coiled material and the plate are actually the same, but the factory form is different. The coiled material is a roll, and the plate is a sheet. If the factory is a plate, it is also called the original plate. It is usually a thick plate because it is very thick. If it is thinner, it cannot be rolled. Generally, it cannot be rolled if it is more than 16 mm.

Stainless steel plates are divided into hot rolling and cold rolling according to the rolling process of the rolling mill (rolling mill is the machine name of the rolling plate). Hot rolling is usually marked as NO.1 and cold rolling is marked as 2B or BA (BA is better than 2B surface, To be bright, close to the mirror, the best is the mirror surface, the mirror surface is not in stock, and it needs to be processed), for example, 304 is often a purchase board, which means that the roll must be flattened into a plate by a machine, this machine is a flattening machine.

3. Main types of stainless steel and their characteristics and uses

304: As a widely used steel, it has good corrosion resistance, heat resistance, low temperature strength and mechanical properties, good hot workability such as stamping and bending, no heat treatment hardening phenomenon, no magnetism, and the use temperature is minus 193 degrees to Positive 800 degrees. Uses: tableware, kitchen utensils, water heaters, boilers, auto parts, medical equipment, food machinery, wine storage, pressure vessels (chemical machinery, chemical equipment).

As a low-carbon 304 steel, 304L has similar corrosion resistance to 304 under normal conditions, but after welding and stress relief, it has good intergranular corrosion resistance and can maintain good corrosion resistance without heat treatment. Corrosion resistance, generally used at 400 degrees, use: petrochemical industry, building materials.

321 adds Ti element to 304 steel to prevent intergranular corrosion, suitable for positive 430 to 900 degrees, non-magnetic; use: automobile exhaust, heat exchanger, container and other products that do not undergo heat treatment after welding, due to the addition of Ti elements, it is not suitable for making food processing equipment.

316 is low carbon, with MO added, so its corrosion resistance, atmospheric corrosion resistance and high temperature strength are particularly good, it can be used under harsh conditions, it is suitable for use below 900 degrees, and it is non-magnetic. Uses: equipment used in seawater, chemical, dye, paper, acetic acid, fertilizer and other production equipment, food industry and facilities in coastal areas, products with special requirements for resistance to intergranular corrosion.

309S/310S, these two kinds of materials, the content of nickel and chromium is relatively high, and the content of Si is increased at the same time, so that it has high temperature resistance and corrosion resistance. Among them, 309S can withstand repeated heating below 980 degrees, and 310S can be used at a temperature of 1200 degrees. Continuous use Temperature can be 1150 degrees, non-magnetic. Uses: Suitable for key parts such as high-temperature electric furnace equipment, drying equipment, furnace materials, aviation, petrochemical, electric power, etc.

The 200 series is similar to the 304 in terms of low price and economy. Uses: Food processing utensils, kitchen equipment, food processing equipment, filters, milk tanks, durable consumer goods, washing machine accessories, water heaters, steel furniture, architectural decoration, decoration. In terms of fatigue resistance, 201 has a higher hardness, but its toughness is not as good as 304, and 304 has better fatigue resistance.